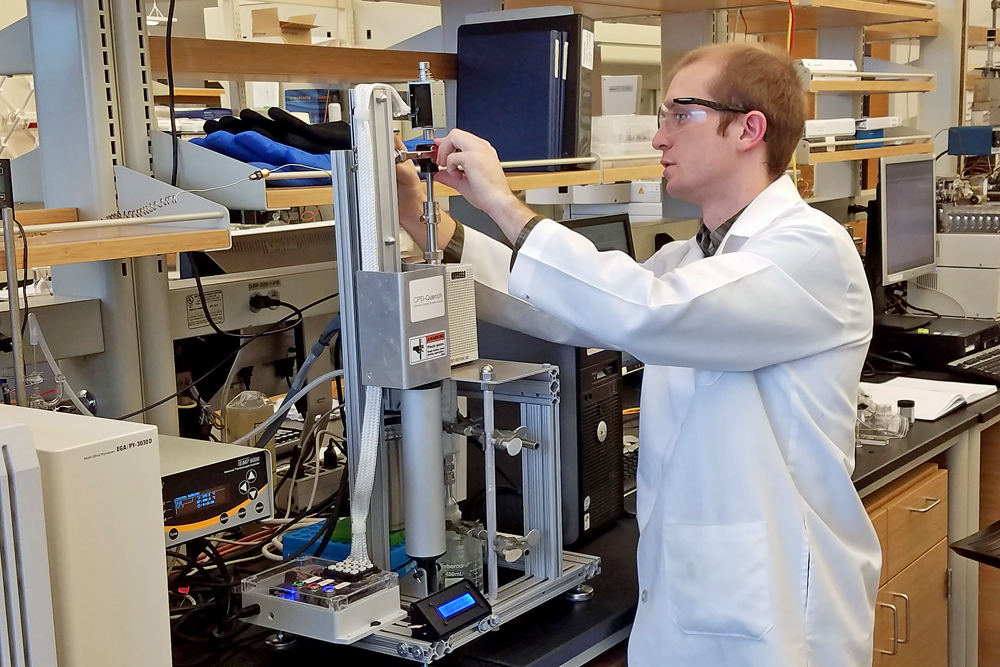

Jake Lindstrom, an Iowa State graduate student in mechanical engineering, loads a biomass sample into a Controlled Pyrolysis Duration (CPD)-Quench reactor. The system helps scientists better understand the products and mechanisms of fast pyrolysis. Larger photo. Photo by Robert Mills/Bioeconomy Institute.

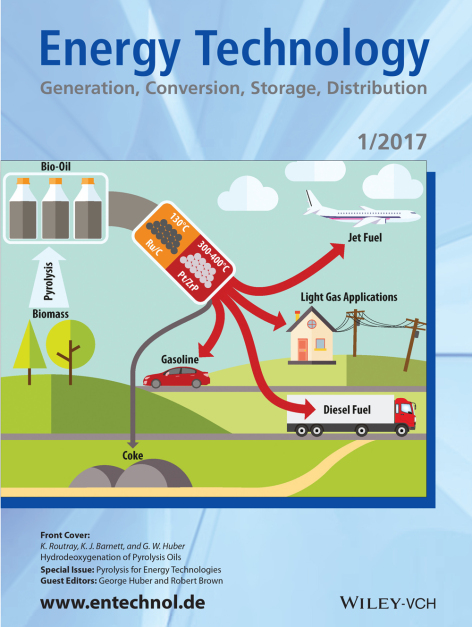

AMES, Iowa – A special issue of the journal Energy Technology details the latest advances in pyrolysis technologies for converting biomass into fuels, chemicals and fertilizers.

Two pyrolysis experts are guest editors of the issue: Robert C. Brown, the director of Iowa State University’s Bioeconomy Institute, an Anson Marston Distinguished Professor in Engineering and the Gary and Donna Hoover Chair in Mechanical Engineering; and George Huber, the University of Wisconsin-Madison’s Harvey D. Spangler Professor of Chemical and Biological Engineering.

“The purpose of this special issue is to highlight recent advances in pyrolysis technologies and to discuss the critical research needs of this field,” Brown and Huber wrote in an editorial summarizing the issue. “We think innovations in pyrolysis will advance more rapidly with improved understanding of the fundamental chemical, physical, and catalytic processes underlying pyrolysis technology.”

The special issue is available online.

Fast pyrolysis as traditionally practiced involves quickly heating biomass without oxygen to produce a biochar for fertilizer and a liquid bio-oil for energy. That bio-oil is the cheapest liquid fuel from biomass today, but it must be upgraded and its oxygen content reduced to produce higher-value fuels and chemicals.

And so, Brown and Huber wrote in their editorial, “To achieve the full benefits of pyrolysis technologies, several advancements must be made to better improve the quality of pyrolysis products and the overall efficiency of the process.”

The guest editors invited some of the world’s experts on pyrolysis to contribute papers to the special issue. The result is 20 scientific papers about all kinds of pyrolysis studies, including sewage sludge as a feedstock, computational models of the chemical reactions, catalytic approaches to producing transportation fuels or commodity chemicals, scaling up to pilot plants and the economic competitiveness of pyrolysis products.

Two Iowa State papers

Iowa State research teams led by Brown and Brent Shanks contributed papers to the special issue. Shanks is director of the National Science Foundation Engineering Research Center for Biorenewable Chemicals based at Iowa State, an Anson Marston Distinguished Professor in Engineering and the Mike and Jean Steffenson Chair in Chemical and Biological Engineering.

Brown’s paper investigates the heating rates and mass transfer of heated vapors in the micropyrolyzer equipment widely used in labs, including Brown’s own lab. The study was designed to test assumptions that microgram-scale studies demonstrate what happens in larger reactors.

“We wanted to test how fast it heated biomass and how quickly the products left the reactor,” Brown said.

The testing, he said, was an “eye-opening process. This study will help researchers understand the limitations of micropyrolyzers.”

The researchers found heating rates in the sample cups were much slower than expected and that the standard sample cups impeded the escape of vapors. They found that substituting shallow, perforated cups helped the vapors escape.

Shank’s paper reviews recent studies of bio-oil processing and upgrading. It looks at treating bio-oil after pyrolysis (which typically involves high pressures and multiple temperatures) or various ways of using catalysts to treat pyrolysis vapors before they were condensed into bio-oil.

The paper concludes that the most promising upgrading technology involves treating the vapors with a catalyst, while using low pressures and moderate temperatures. The resulting bio-oil would be suitable for further refining in a traditional petroleum refinery.

That still produces a complex mixture of molecules that can’t be used directly, said Shanks, whose lab has studied the chemistry of bio-oil and is beginning a new study of how catalysts can be used to upgrade pyrolysis vapors.

“No one has perfected the technology, but it’s worthy of further exploration,” Shanks said.

Enthusiasm and additional research

All in all, Brown said the special issue of Energy Technology shows the advancement and understanding of pyrolysis technologies has grown tremendously over the past five years.

While advanced biofuels are still too expensive to make it in the marketplace, Brown said thermochemical processes such as pyrolysis have high prospects for producing renewable fuels and chemicals.

“This special issue illustrates a great enthusiasm for the field of pyrolysis,” he said. “It helps identify where additional research is needed to make pyrolysis a practical reality.”