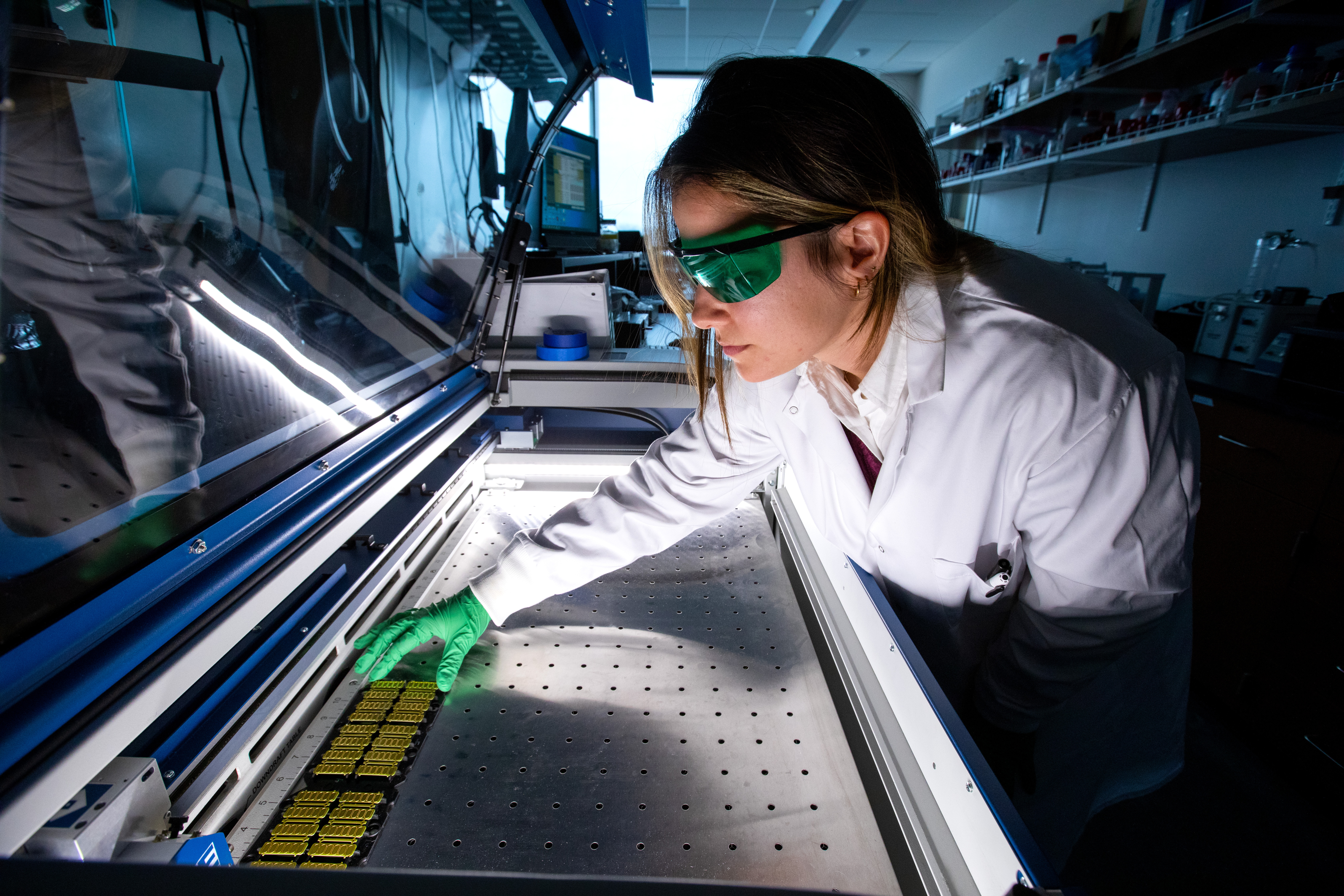

In a Sukup Hall lab, Ph.D. student Raquel Rainier places circuit boards to be charred by a laser to create graphene. When an ion-selective membrane is added, the circuits are a sensor for nitrate and ammonium. Associate professors of engineering Carmen Gomes and Jonathan Claussen lead the research team that created the technology. Photo by Christopher Gannon. Larger image.

By Dave Roepke, News Service

For more than 150 years, Iowa State University scientists have helped support agricultural production. It’s a foundational mission, present from the start and persisting to this day. In a broad sense, the goal of that research hasn’t changed. Farmers who know more grow more.

But the advances in precision and digital agriculture that Iowa State researchers are creating for modern agricultural operations are focused more than ever on information. Successful farming is increasingly fueled by data and automation, innovations that can boost yields and profits while improving sustainability. Often by building their own products or partnering with companies, ISU researchers give farmers tools for making better decisions.

“We’re trying to reduce risk, to reduce stress, and to use technology to make farming more resilient,” said Matthew Darr, professor of agricultural and biosystems engineering.

Instant insight

An EnGeniousAg sensor shows the nitrogen level in a corn stalk within seconds. Photo by Christopher Gannon/Iowa State University. Larger image.

One of the vexing decisions farmers face is how much nitrogen to apply to their crop. Nitrogen is an essential nutrient for plant growth, and farmers often use fertilizer to ensure their crops have enough nitrogen to thrive. That’s especially important for corn, which can’t pull nitrogen from the air as soybeans do. But there are major downsides to applying too much fertilizer or at the wrong time. Nitrogen that washes away can overstimulate algae growth in rivers and lakes, choking off bodies of water and polluting drinking water. It’s also a financial drain for farmers.

“Getting the optimum nitrogen rate for corn is very important because right now it’s the most expensive input cost for producing corn, which has among the highest input costs of any major global crop,” said Michael Castellano, professor of agronomy. But it’s difficult to forecast ideal rates, which can vary from field to field and from year to year within the same field, he said.

Soil testing provides insight, but collecting samples for lab testing is labor-intensive and time-consuming. Affordable sensors that quickly and accurately measure nitrogen levels would help farmer get closer to perfecting their fertilizer rates and make it easier for them to use conservation-minded practices such as applying before and after planting. That’s the goal of two research teams at Iowa State who have designed nitrogen sensors they plan to commercially release as early as next year after field testing this summer.

Castellano is one of the co-founders of EnGeniousAg, a startup whose other founders include Patrick Schnable, distinguished professor of agronomy and director of the Plant Sciences Institute; Liang Dong, professor of electrical and computer engineering; and James Schnable, professor of agronomy at the University of Nebraska-Lincoln. EnGeniousAg’s handheld sensor measures the concentration of nitrate, a nitrogen compound, in the stalk of a plant. Detecting nitrate levels in a plant should improve accuracy of fertilizer recommendations as compared to using soil tests, because it is a measure of how much nitrogen has been absorbed instead of how much is available. Farmers also appreciate the speed.

“You stab it and get your reading within seconds,” said Dong, whose research produced two patents EnGeniousAg licenses to create the device.

A team headed by associate professors of mechanical engineering Carmen Gomes and Jonathan Claussen has partnered with Van Wall Equipment, an Iowa-based equipment dealer, to add nutrient sensors to an existing moisture monitoring probe. Integrating their Nutriprobe device with Van Wall’s Aquacheck soil moisture sensor offers constant remote monitoring of nitrate and ammonium, another nitrogen compound plants absorb from soil. The probe is designed to stay in the ground for an entire growing season.

Both sensors rely on ion-selective membranes that repel all but certain molecules, the ions of interest, then measure the voltage of what passes through the membrane to detect the concentration. Claussen and Gomes mount their membrane on plastic circuit boards that have been charred with a laser engraver to cheaply and easily create graphene, a single-atom thick form of carbon renowned for its strength, stability and conductivity.

Getting to market

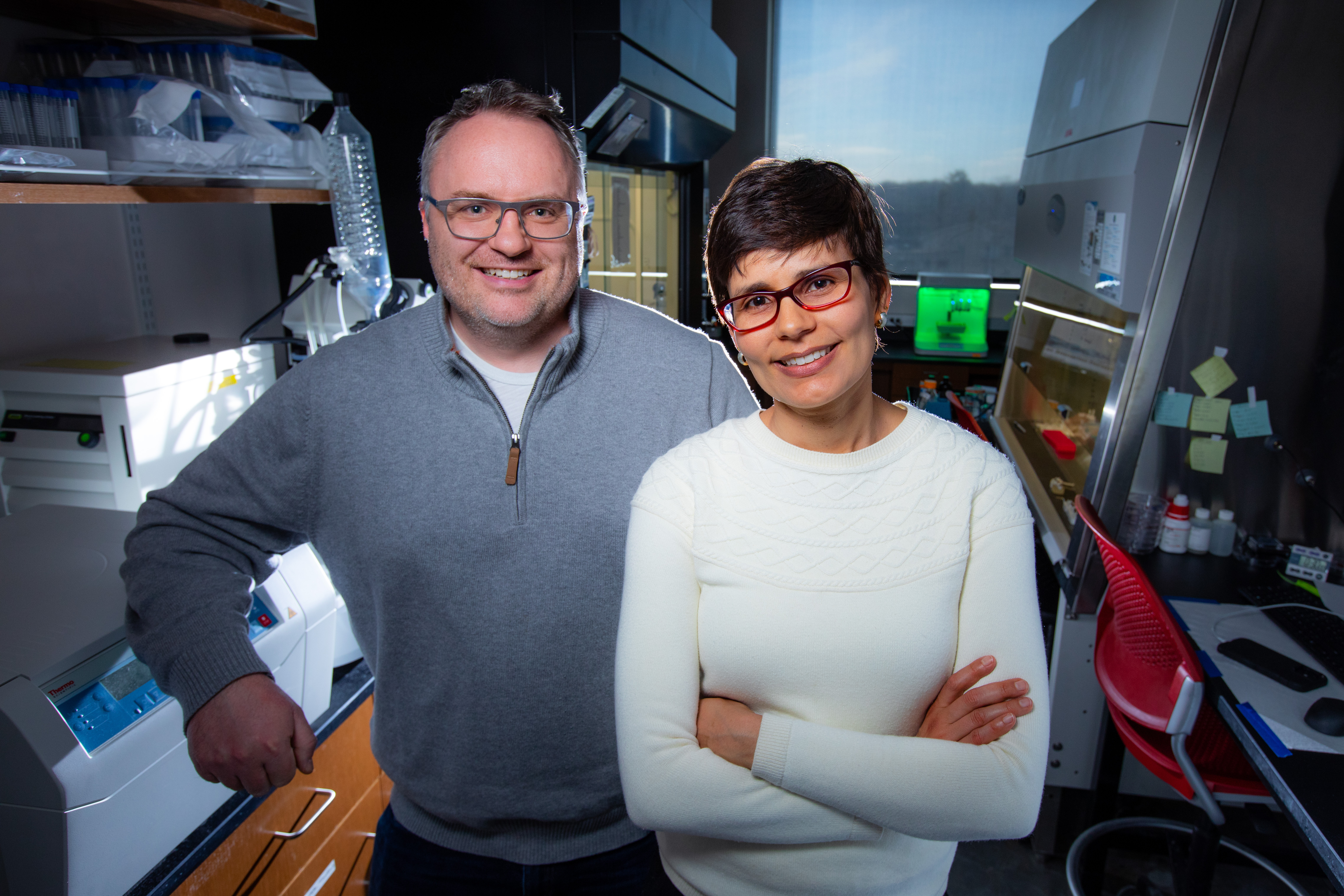

Jonathan Claussen, left, and Carmen Gomes, associate professors of mechanical engineering, in their Sukup Hall lab. Photo by Christopher Gannon/Iowa State University. Larger image.

Claussen and Gomes have worked to develop graphene-based sensors for a variety of other purposes – including COVID-19 testing and food safety – but the Nutriprobe has advanced the closest to hitting the market in part because of the expertise they’ve tapped by pairing with industry.

“It’s been a great partnership because we understand graphene technology and ions, but Van Wall is one of Iowa’s biggest John Deere dealers. They understand what farmers are looking for,” Gomes said.

Gomes said working with Van Wall and farmers testing the device has clarified future research plans, which include a soil salinity sensor. They’ll also continue to work on improving durability and production cost, which is currently less than $1 per unit. A practical outlook is natural for a sensor researcher, but developing a commercial product makes the inclination more urgent, she said.

“We have to think about the purpose of things. You don’t want to invent a hammer that needs to look for nails,” she said.

Iowa State’s participation in a new federally funded center for soil health technology, SoilTech, is likely to lead to more private sector collaboration for Claussen and Gomes, who are co-directors of the ISU site for the industry-focused center.

An affordable process for making graphene drives down the cost of the nitrogen sensor created by Jonathan Claussen and Carmen Gomes. Photo by Christopher Gannon/Iowa State University. Larger image.

“I think we’re just on the cusp of the role sensors can play in driving down costs for farmers while addressing some of our environmental issues at the same time,” Claussen said.

EnGeniousAg also has an industry partner in testing its nitrogen sensor. Premier Crop Systems, an Iowa-based precision agriculture company, plans to use the EnGeniousAg device in some of the nitrogen-rate experiments it is running with farmers. Soilview, a soil-sampling company, will test soil from the same plants to compare the cost and accuracy to conventional methods. EnGeniousAg already conducted an early round of testing with some volunteers from the Iowa Corn Growers Association, which prompted some adjustments, Patrick Schnable said.

“We learned that we need a very simple-to-use and rugged device. That has really guided development since,” he said. “Farmers are not interested in reading a 20-page instruction manual.”

Two Small Business Innovation Research grants – $100,000 from the U.S. Department of Agriculture and $225,000 from the National Science Foundation – have helped EnGeniousAg progress since its founding in 2018, as has institutional support from Iowa State’s Innovation Corps and Startup Factory programs. EnGeniousAg has a full-time employee, Xinran Wang, an ISU graduate who worked on the probe as part of her doctoral research.

“We’re really fortunate that Iowa State allows faculty time to engage in entrepreneurship activities,” Schnable said. “Because this could have a huge impact on the world and for economic development in the state.”

Constant collaboration

Working with companies on product development isn’t a side project for Darr’s Digital Ag Innovation team. Industry partnerships are the whole point.

“We don’t set a specific research agenda. We adapt our research agenda to help partners be successful,” Darr said. “We use engineering and science to solve complex problems within agriculture that ultimately add value – sometimes for farmers, sometimes for consumers, sometimes for the environment.”

Matthew Darr with Ellen Barrett of John Deere, talking about the needs for college graduates in the high-tech ag industry. Photo by Buffy Clatt/ISU Research Park. Larger image.

The emphasis on private sector collaboration has produced results. In hundreds of projects over the past 15 years, Darr’s team has generated more than 70 licensed patents and technologies – contributing to more than 30 commercial products, most related to farming equipment. The Digital Ag Innovation team typically accounts for about half of Iowa State’s corporate-funded research.

A devoted approach to industry is somewhat rare for an academic research group, but Darr said it maximizes his team’s impact, strengthening an important economic engine in Iowa and giving students valuable experience working with potential future employers.

“Iowa State doesn’t sell tractors. We need to collaborate with partners who have the delivery mechanisms for our technology to reach farmers and impact agriculture,” he said.

The 60-member Digital Ag Innovation team includes about 45 professional and scientific staff with backgrounds in engineering, design, data science, coding and agronomy. The team's work with corporate sponsors benefits from the continuity of professional staff while also creating unique experiences for graduate and undergraduate students. Projects involve a level of cooperation and communication that enables high-impact outcomes.

“Most of our projects have a daily collaborative touch point between ISU and our industry partners as we work through the innovation process,” Darr said.

A second tenure-track faculty member, assistant professor of agricultural and biosystems engineering Bailey Adams, joined the team full-time in fall 2022 after earning his doctorate for research conducted with the group. He said the team’s work has three core areas of excellence:

- Controls and automation, which often involves model-based software development

- Algorithms and sensor technology, typically involving advanced signal processing

- Digital agronomy, including remote sensing and high-definition plant management

Digital agronomy research manager Ryan Huffman preparing planter equipment for innovation at the cross section of agronomy and engineering. Photo courtesy of Digital Ag Innovation team. Larger image.

“There are so many different flavors of autonomous systems across a wide variety of machinery platforms that our team is helping to develop,” Adams said. “The ultimate goal is to relieve the decision-making process for farmers by enabling intelligent control systems to evaluate job quality and autonomously make the proper adjustments for optimal performance.”

Noting that farm equipment has had auto-steer technology since the late 1990s, Darr likened his team’s automation research to efforts to optimize manufacturing processes. “When you’re driving a combine, you’re really driving a mobile factory. We’re perfecting how that factory operates, which is just as important as it is on an assembly line,” he said.

Model-based virtual engineering is an increasingly powerful tool in the search for those improvements, Adams said. It’s an efficient way to create, test and tweak designs before in-field verification. Modeling lowers development costs and keeps projects moving even in the winter when physical trials are limited if not impossible.

“That’s something our sponsors have more and more appetite for,” Adams said.

Keys to success

Senior engineering manager Alex Lassers came to work for the Digital Ag Innovation team after working with its researchers on numerous projects in his 15 years at John Deere, a frequent partner for Darr’s group. He said companies value the team’s flexibility in finding solutions to questions where there are more unknowns than knowns. Figuring out how to test and measure new technology is often half the battle, and initial concepts usually change.

“One of this team’s core abilities is getting partners the data they can really trust when making big decisions. The thought leadership our team provides allows our partners to align data with company mission and business targets, which results in measurable performance,” Lassers said.

A new centralized home – the recently announced plans for the Alliant Energy Agriculture Innovation Lab, a new building at the ISU Research Park expected to be built by fall 2024 – provides a foundation for further expansion of a team currently spread across a variety of locations, including the BioCentury Research Farm.

Darr said industry partners often cite multiple reasons for working with the Digital Ag Innovation team, including identifying student talent and connecting with Iowa State’s diverse research expertise.

“Universities are inherently interdisciplinary. Companies are not. The structure of a company is set up to ultimately sell products and solutions. You’re not going to have a materials science division and a biology division and an agronomy division and an organic chemistry division within a single company. But this level of diversity is common to universities,” he said.

Supportive infrastructure also is a big reason for the team’s success, Darr said, including the research park and the university’s office of innovation commercialization.

“None of us could be successful in a vacuum. It takes working together to accomplish our goals,” he said.

A powerful tool

Almost a decade ago, shortly after Arti Singh began working at Iowa State, a presentation hosted by the Plant Sciences Institute piqued her interest. Baskar Ganapathysubramanian, professor of mechanical engineering, was telling an audience of Iowa State plant scientists about the latest advances in artificial intelligence.

“He was discussing how machine learning could transform computer vision and gave as an example differentiating between cats and dogs,” said Singh, assistant professor of agronomy. “I thought that if it works for cats and dogs, it could work for soybean diseases.”

Arti Singh, assistant professor of agronomy, takes insect pictures in July 2022 in a field at the Ag Engineering/Agronomy Research Farm. Courtesy of Arti Singh. Larger image.

Since then, Singh has been collaborating with the Soynomics research team to achieve their goal of providing AI vision to drones and robots for real-time plant stress identification, classification, quantification and prediction within the framework of integrated pest management.

Singh, Ganapathysubramanian and co-workers first built an app that identified a handful of soybean diseases before pivoting to insects, where the technology could be even more useful. There are about 90,000 identified species of insects in the United States, and many of their geographic ranges are in flux due to climate change. Unknown insects aren’t an uncommon sight in farmer’s fields, and an infestation can devastate a crop in a matter of days.

“By the time you know an insect is a pest, it could be too late,” Singh said.

The insect identification app Singh and Ganapathysubramanian are developing provides instant answers, a powerful head start for pest control. In addition to identifying an insect’s species, the full version of the app will supply crucial management information such as which stage of an insect pest is relevant for scouting and the control measures to mitigate the stress.

“In the future, I think this is a tool every single farmer will have in their pocket,” Singh said.

The work was possible due to collaboration by the interdisciplinary Soynomics team of faculty, staff and students, including the lead graduate student on the insect identification project, Shivani Chiranjeevi, who is co-advised by Ganapathysubramanian and Singh. It also has provided learning experiences for other graduate students, undergraduates and even high school students. Funding for the research has come from a variety of state, commodity group and federal agencies, including the AI Institute for Resilient Agriculture, a multi-institution research center based at Iowa State and led by Ganapathysubramanian.

Harnessing AI

Building a system that identifies insects based on a photo is challenging for a variety of reasons. Many species look alike, blend into their surroundings and go through various life cycles. A larger set of images increases accuracy, but only if they’re iddentified correctly in the first place.

“If you have 1,000 images of cats and dogs, you need to know which images have cats and which ones have dogs. This makes an annotated data set,” Ganapathysubramanian said. “Data is worth its weight in gold, especially when it’s annotated.”

The solution has been a type of artificial intelligence similar to what underpins natural language chatbots and AI-powered image generators. The deep learning models that power the insect app can learn from a relatively small amount of annotated data and generalize to make accurate predictions across large data sets, applying lessons gleaned from photos of identified bugs to annotate unmarked photos, Ganapathysubramanian said. Results of a search also include a rating for how confident the model is in its answer.

Baskar Ganapathysubramanian, professor of mechanical engineering, is the director of the AI Institute for Resilient Agriculture. Photo by Christopher Gannon/Iowa State University. Larger image.

“Confidence is critical because if you make a mistake, it could have economic impact,” he said.

Unleashing the deep learning models on public sets of insect images has expanded the app’s photo library to 6 million images, an exponential increase from the 30,000 pictures taken in summer 2021 with help from a team of students. When Singh demonstrated the app at the Farm Progress Show last fall, it could identify about 1,000 species. Now, it can spot more than 2,500, with an average per species accuracy of more than 95%.

“I can’t identify 2,500 species of pests, but AI can,” Singh said.

The rapid buildup of the app’s power at times has even surprised Singh. As she was reading news last summer of a spotted lanternfly being found in Dallas County in Iowa, she scanned a photo of the invasive species to see if the app recognized the destructive bug accidentally introduced to the United States in 2014. She was unsure if it would, but it did. “Do you realize the implications?” she recalled asking Ganapathysubramanian in an excited phone call.

The app will be field tested by a small group of farmers and extension experts this summer before a public version is released, Singh said. While there are no partnerships in place for commercial use, they have met with some interested parties, she said.

“We want to have an impact by being open to all, but there may be some opportunities to license it,” she said.

Singh envisions limitless future possibilities. An insect identification app could be mounted on a sprayer or incorporated with pesticide-dispensing drones and robots for optimal surveillance and accuracy. It could be used at customs checkpoints to stop the spread of invasive species.

"I believe what we've already accomplished is remarkable," Singh said. "However, this tool possesses massive potential that has yet to be realized."

Patents, Inventions and Discoveries

Innovation at Work is a series of stories, photos and videos highlighting the collaborative efforts of Iowa State researchers to develop innovative solutions, products and technologies. Visit the Innovation At Work story gallery and read the other entries in the 2023 series:

#IowaStateInnovates

Advances in precision and digital agriculture created at Iowa State are focused more than ever on data, innovations that can boost yields and profits while improving sustainability. Often by building their own products or partnering with companies, ISU researchers give farmers tools for making better decisions.

Sensors in the soil all season

Quotes

“It’s been a great partnership because we understand graphene technology and ions, but Van Wall is one of Iowa’s biggest John Deere dealers. They understand what farmers are looking for.”

Carmen Gomes, Mechanical Engineering

“When you’re driving a combine, you’re really driving a mobile factory. We’re perfecting how that factory operates, which is just as important as it is on an assembly line."

Matthew Darr, Agricultural and Biosystems Engineering

“In the future, I think this is a tool every single farmer will have in their pocket.”

Arti Singh, Agronomy