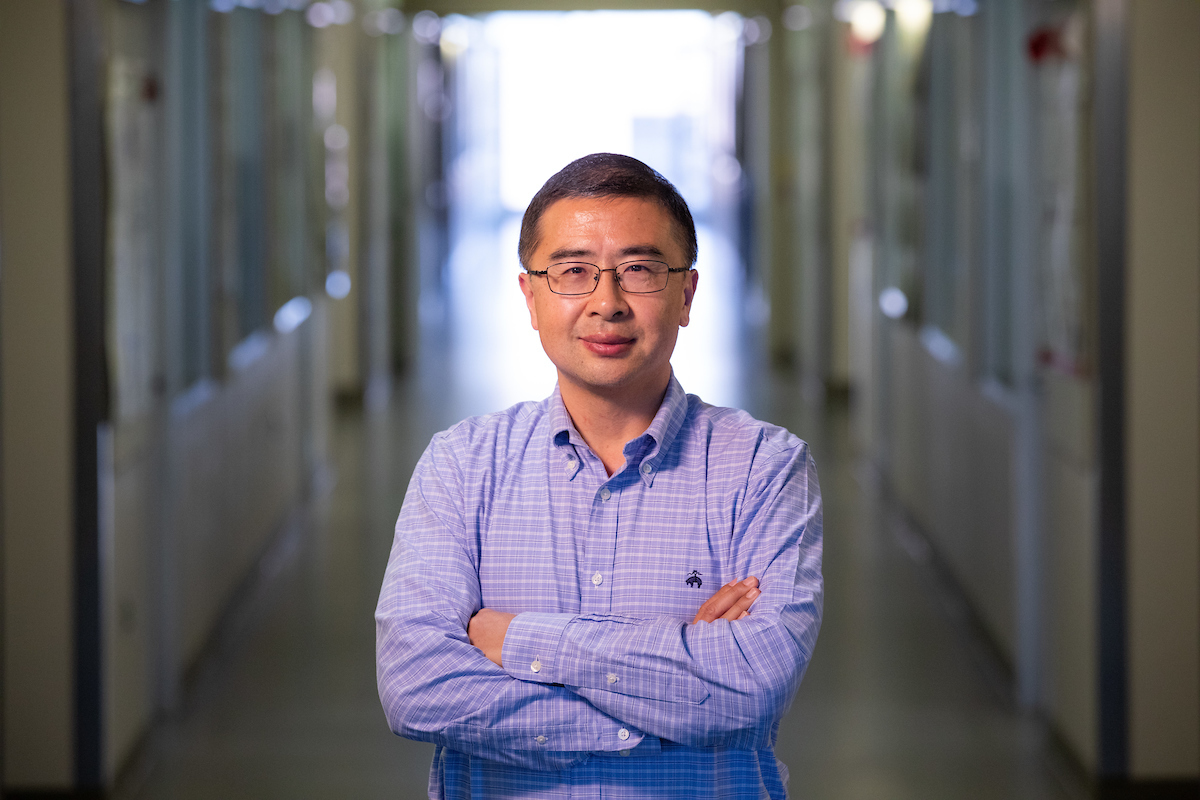

Yan Zhao is working to develop synthetic catalysts that could help industry break down plant fibers for fuels and chemicals. Larger photo. Photo by Christopher Gannon.

AMES, Iowa – Yan Zhao gestured toward the trees outside his campus window on a rainy afternoon.

The professor of chemistry at Iowa State University is developing new synthetic catalysts to break down cellulose, the plant fibers that make those trees tall and strong.

“Cellulose is built to last – a tree doesn’t just disappear after rain,” Zhao said. “Cellulose is a huge challenge to break down.”

Zhao thinks he has an idea and a technology that can get the job done, making plant biomass a practical source of sugars that can be converted to many applications, including fuels and chemicals.

Learning from Mother Nature

“We’re taking our inspiration from biology,” Zhao said. “We’re trying to duplicate the features of natural enzymes. And so far, we have good results.”

Enzymes are natural proteins that act as catalysts, regulating the chemical reactions that keep biological processes going and living beings functioning. Enzymes, for example, catalyze cell metabolism, including breaking down food for digestion.

Three enzymes – endocellulase, exocellulase and beta-glucosidase – can break down and digest plant fiber, or cellulose.

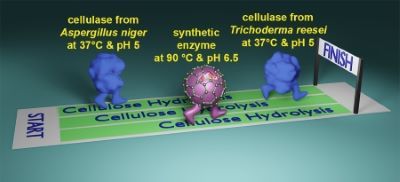

Natural enzymes would seem to be a good place for industries to turn for cellulose processing. But they’re expensive. They can’t survive high temperatures or nonaqueous solvents. And they’re unstable and difficult to recycle back into production.

Zhao’s research group has worked about 10 years to develop nanoparticle catalysts capable of resolving those issues. Grants from the National Institutes of Health and the National Science Foundation (NSF) have supported that work. The Iowa State University Research Foundation is pursuing patent protection of the technology and is seeking commercial partners.

A new, three-year, $700,000 grant from the NSF (with $400,000 for Iowa State research) will advance Zhao’s latest ideas about enzyme-mimicking catalysts. The new project includes computer simulations of the active reaction sites by Sijia Dong, an assistant professor of chemistry and chemical biology at Northeastern University in Boston.

The simulations, Zhao said, “will help us to better understand our system. This is a very complex system.”

Making the most of micelles

Zhao’s research group is taking advantage of dynamic nanospheres known as micelles. They assemble themselves when chains of surfactant molecules (which reduce surface tension in liquids) are exposed to water, causing the hydrophilic, water-loving heads of the molecules to form an exterior shell and the water-hating, hydrophobic tails to turn inside that shell.

Zhao and his group have found a way for micelles to assemble around active-site-resembling template molecules. Once solidified by ultraviolet light, these “molecularly imprinted nanoparticles” are 5 billionths of a meter in size and have the exact shape and size to mimic the binding and catalytic properties of natural enzymes. The nanoparticles have catalytic groups directly pointed to sugar linkages in cellulose polymers to break them down efficiently and selectively.

“If successful, the research will yield synthetic catalysts for cellulose (breakdown) that can compete with natural cellulases in activity but are much easier to prepare and recycle,” according to a project summary.

That could make them a viable option for industry, said Zhao, who’s interested in establishing partnerships with companies.

The technology, after all, fits the state and the times.

“Biomass conversion is a big deal not only to the state of Iowa,” Zhao said, noting a potential market for the biomass grown in farm fields across the state, “but the world right now is interested in a carbon-neutral economy and sustainability.”