The students of Cardinal Space Mining are testing their ideas and their machine during the Robotic Mining Challenge at the University of Alabama. Larger photo. Photo courtesy of Cardinal Space Mining.

5-13-19 update: The first mining run for Cardinal Space Mining at the Robotic Mining Challenge at the University of Alabama turned into a data run. One of the robot’s tracks wasn’t working, leaving the machine stalled in the mining arena’s staging area. But, the team buried its trenching arm into the simulated Martian soil anyway. Team members hadn’t had time to test their machine, so they went after buried gravel representing subsurface ice – and as much performance data as they could collect, said Amir Hamza, the team’s president. The team took that data and applied it to a second mining run that resulted in more than a kilogram of mined gravel before a broken chain on the trencher stopped mining operations. But, the team had demonstrated that its new, hybrid trenching-loading system worked. And the team learned one other lesson: “If we would have had more testing,” Hamza said, “we would have been in a much better spot.”

---

AMES, Iowa – After the challenges – and breakdowns – of taking their robot in a new direction last year, the student-engineers of Cardinal Space Mining have been problem-solving.

Last year’s robot for NASA’s annual Robotic Mining Competition was really a heavy-duty trenching machine. It was all about digging into dusty, gritty simulated Martian topsoil to get at buried gravel representing subsurface ice. On Mars, that ice could be very valuable as a potential source of oxygen, water and fuel.

After digging into the soil like a chainsaw, the trenching arm was also supposed to pick up and load the gravel for later dumping and weighing.

Well …

“Last year was a development year,” said Nic Romero, a senior studying mechanical engineering from Oregon, Wisconsin. “We were testing a design that no one had tried before. We gave it our best shot and did see the concept had promise.”

But, the team also learned that trenching and loading are really two different jobs, said Taylor Goodness, a senior mechanical engineering major from Lakeville, Minnesota.

“We learned a lot of lessons,” Goodness said. “We learned the trencher worked well below ground, but didn’t work above ground.”

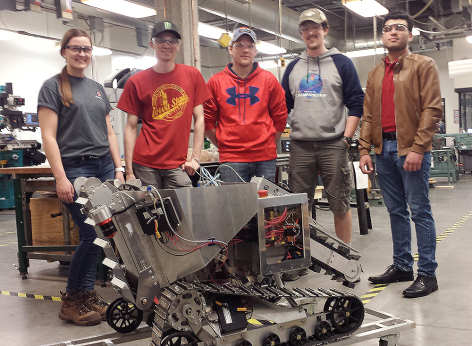

Cardinal Space Mining members, left to right,Taylor Meyer,

Nic Romero, Taylor Goodness, Nathan Butler and Amir Hamza.

So the team is unveiling a new hybrid mining machine this year, said Amir Hamza, a junior from Pakistan who’s studying computer engineering and is the team’s president. The robot’s trenching arm will dig down about 18 inches and pull buried gravel to the surface. And then a bucket-ladder system will pick up the gravel and dump it into the robot’s hopper.

Team members are calling the machine “Marineris,” after Valles Marineris, a Martian canyon about 1,900 miles long.

Unfortunately, Iowa State students and their counterparts across the country won’t be testing their new ideas and machines at NASA’s Kennedy Space Center in Florida, the traditional home of the Robotic Mining Competition. NASA suspended the competition this year, citing delays in preparing a new, indoor competition arena.

But, students will still compete in a “virtual” competition based on submitted engineering plans, a systems engineering paper, a report about outreach activities and a videotaped slide presentation. Taylor Meyer – a senior in mechanical engineering from Maple Grove, Minnesota, and the team’s vice president – said Iowa State has submitted its entry.

In addition, the University of Alabama, winner of five robotic mining championships (including the last four), has invited teams to compete this week in its new mining lab. Nearly 30 teams, including Iowa State’s team, have accepted the invitation.

Cardinal Space Mining’s two, 10-minute competition runs are scheduled for Wednesday, May 8, at 5:35 p.m. and Friday, May 10, at 8:50 a.m. The mining runs will be livestreamed on the Alabama Astrobotics YouTube page.

How will it go this year?

Hamza said the team likes the new digging and loading system. And team members have worked hard to develop telemetry, camera and communications systems that will allow the robot to operate without students picking up the remote controls. If the team succeeds in autonomous operation, it can earn up to 500 extra mining points for each run.

“We have high hopes,” Goodness said. “But there’s always the risk of facing challenges.”

This is "Marineris," the latest mining machine designed and built by the student-engineers of Cardinal Space Mining. Larger photo. Photo courtesy of Cardinal Space Mining.