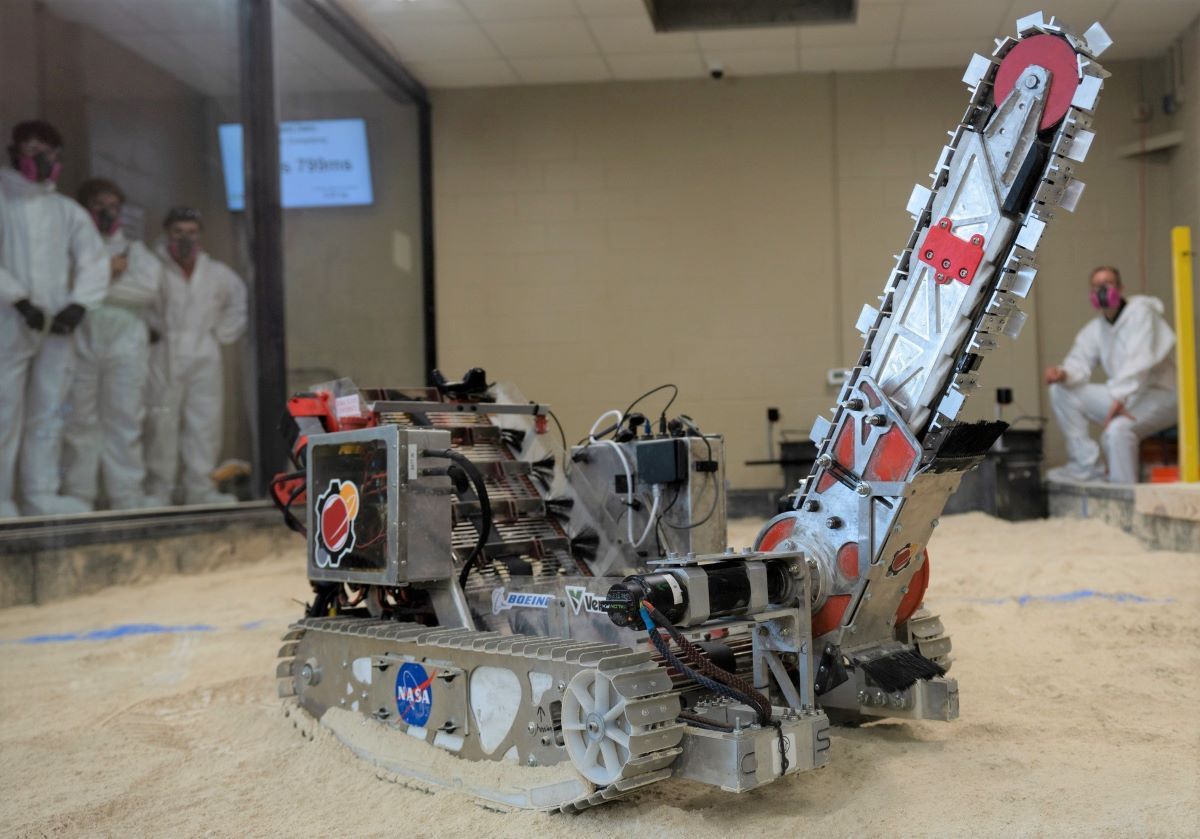

The students of the Cardinal Space Mining Club designed and built a winning, powerful and autonomous robot. Larger photo. Photo courtesy of the Cardinal Space Mining Club.

AMES, Iowa – “MARS Atlas,” a high-tech mining robot built by Iowa State University students that’s equipped with lidar-sensing technology and the computing power for autonomous operation, is also a bit of a bulldozer.

A rock is in the way?

The robot’s lidar system (Light Detection and Ranging, which includes laser, GPS and navigation units) is supposed to see that rock and steer the robot around it. Until, well, it doesn’t.

That’s what happened during a mining run at the recent Robotic Mining Challenge sponsored by Caterpillar Inc. at the University of Alabama in Tuscaloosa.

The contest’s mission is for students across the country to learn some science, technology and engineering by designing and building robots that can autonomously navigate a dusty, rocky simulated lunar landscape. Then the robots need to dig up, collect and deliver simulated ice (chunks of gravel) buried about a foot below the surface.

Digging up ice is about making long-term missions on the moon possible. The lunar ice would be a source of water and oxygen for moon dwellers.

So, Iowa State’s Cardinal Space Mining Club sent its MARS Atlas robot into the mining arena to see how many kilograms of ice it could collect. (That name? It’s the latest in the club’s MARS series of robots – the contest used to simulate mining on Mars – and Greek mythology’s Atlas was strong enough to hold up the heavens and an atlas is also a good place to plot a path.)

A team video shows the robot activating its tracks and heading to the designated mining area. But there was a rock the size of a soccer ball in the way. Atlas didn’t steer around it. Instead, Atlas dug in its tracks and pushed that rock several feet across the gritty, loose soil and into the mining area.

But that bug in the obstacle-detection system didn’t stop Atlas from operating autonomously for most of that mining run. The robot successfully collected and delivered four loads of simulated ice in 15 minutes.

Atlas was so powerful and so independent, it won the contest’s mining competition and took second place in the contest’s autonomy competition. The club also won the grand prize at NASA’s online Lunabotics Challenge, including top spots for its systems engineering paper and its presentation and demonstration.

“This is truly the best year in the club’s history,” said Jim Heise, the club’s long-time faculty advisor and a professor of practice in mechanical engineering. The last time the club won a championship was 10 years ago, when the club called itself “Team LunaCY.”

The club’s winning formula

Ask about the key to this year’s success, and Nathan Butler, a May Iowa State graduate in mechanical engineering from Riverside in eastern Iowa and a future Oregon State graduate student in robotics, talks more about people and project management than technical upgrades by the systems, controls and mechanical teams.

It really helps that club members come back to the competition year after year, said Butler, who has been part of the club since his freshman year.

Some teams enter the competition as one-off senior projects. “Students learn, graduate and that knowledge is lost,” Butler said.

That’s not how it works around Cardinal Space Mining.

“There’s sustained support of the team,” he said. “The faculty advisor has done this for over a decade. There are big sponsors (Boeing, Caterpillar, the College of Engineering, Danfoss, the Engineering Student Council, the Iowa Space Grant Consortium, Student Government and Vermeer) that we can count on every year. And this year there were a lot of dedicated members – this was a team that was performing.”

Leaders knew team members’ strengths and weaknesses, he said. Leaders could delegate accordingly. And members put in the time and did the work.

Heise said a major result of that management approach was a robot ready for testing in mid-March. That gave the club weeks to test, assess and refine their machine.

Kiah Christopherson, president of the club and a senior in mechanical engineering from Burnsville, Minnesota, said the secret to the club’s success really was its people power.

“The team’s success this year is because of the amazing group of people who make up our club and are willing to learn and grow with each other,” she said. “We have so many talented and dedicated members on this team that made it possible to win both competitions.”

Thanks to the work of all those club members, Heise said, “There is some serious power in this robot.”